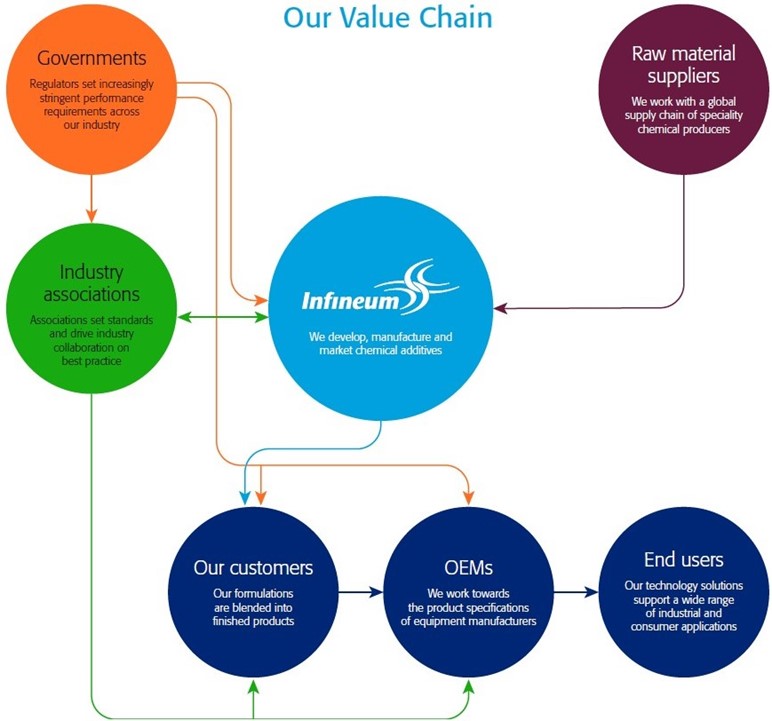

Our business ecosystem

For many years, Infineum has been driving innovation across the lubricant and automotive industry that has

enabled performance and efficiency improvements. As a partner to many Original Equipment Manufacturers (OEMs) in the transportation sector and through a leading role in industry groups, Infineum has supported the definition and development of many new specifications that have driven, and will continue to drive, improvements in lubricant performance, including lower in-use emissions.

By working together with our customers, OEMs and industry partners, we are enabling the development of low-emission vehicle technologies and supporting the electrification of mobility. We expect this collaboration to continue, as emissions legislation and performance standards become increasingly ambitious.

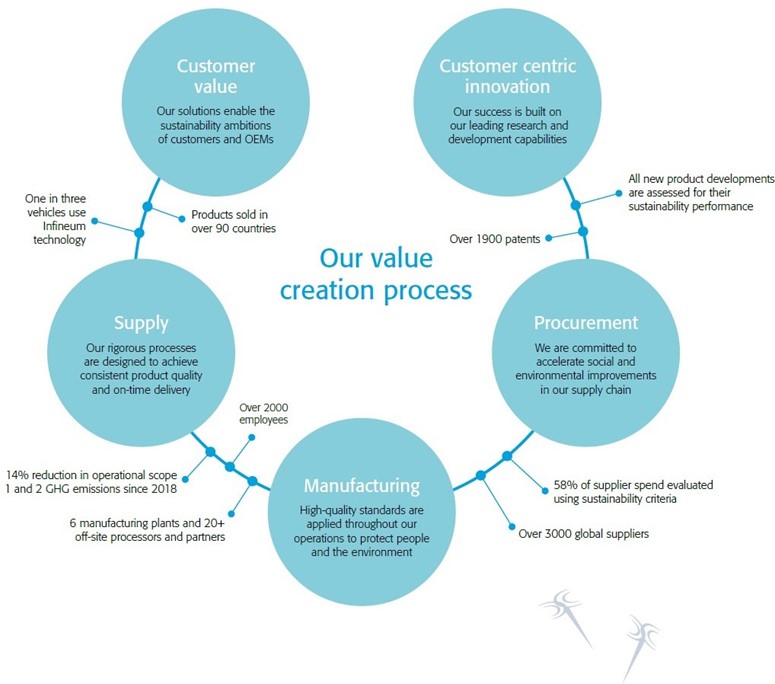

How we create value

With more than 1,900 global patents, our technology excellence is backed by rigorous processes that ensure reliability, consistency and quality from product development through to end delivery. We pride ourselves on our strong and collaborative customer relationships and continually work to develop the appropriate capabilities and resources to help them meet their business and technical goals.

Through powerful research and development capabilities, Infineum technology supports the creation of best-in-class products. Our fundamental technical competencies of detergency, dispersancy, surface chemistry, flow improvement and wax modification enable fuels and lubricants to deliver better fuel economy, reduced emissions, and less waste through longer oil drain intervals and extended engine life.